Reuse Redeploy Regenerate

Husk Flexible Life Buildings - relocatable construction

About Husk

HUSK a redeployable and reusable, low carbon, Flexible Life Building system developed for use on urban, meanwhile, or temporary spaces.

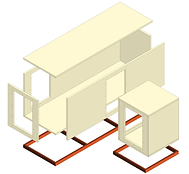

The HUSK system features 3 mass timber reusable modules and a limited range of interchangeable components designed for resource-efficient, adaptable construction. Using mass timber CLT panels and simple universal connections, HUSK allows seamless integration of new, reused, or recycled materials whilst utilising single or multisource manufacturing. The simple design of the stackable foundationless modules can be easily deployed, relocated, or reconfigured to suit changing site needs, with minimal environmental impact. Ideal for temporary developments (5-10 years or longer), HUSK transforms underutilised meanwhile and temporary sites into vibrant, community-focused spaces while promoting urban renewal, carbon reduction, and material reuse.

Deploying Husk

HUSK FLBs are modular, foundationless, and adaptable —designed for rapid deployment, relocation, and reconfiguration, integrating new, recycled or reused components in a single deployment

Stage 1: Prepare the ground, deliver fabricated components, and commence assembly.

Stage 2: Connect and join HUSK modules.

Stage 3: Install pre-made insulated cladding and roofing cassettes, doors, and windows.

Stage 4: Interior fit out, connection of MEP and completion

Stage 5: Dismantle for reconfiguration and redeployment.

Stage 6: Redeploy and rebuild, integrating additional and existing modules and components.

Sustainability

HUSK redefines sustainable construction with foundationless, reusable buildings reducing carbon emissions and embracing the circular economy — maximising material reuse and minimising waste

This work is a progression of the outcomes from the government match funding Design Challenges for a Circular Economy as led by Jon Baker in partnership with the Alliance of Sustainable Building. It is also a continuation of research into sustainability within re-useable construction and the built environment.

Foundationless and reusable construction is still one of the most effective techniques to employ to reduce carbon emissions. This aligns with the principles of the circular economy, “Keeping resources in use for as long as practical then, re-purposing and regenerating at the end of their life”.

To achieve our goal of a net zero building system, Where possible, FLBs will use renewable and recycled materials and strive for a 90% material re-use during the life cycle of the modules and components, with the remaining 10% re-purposed or recycled.

HUSK actively utilises and promotes sustainable building products, materials and construction techniques partnering likeminded companies and organisations who share our ethos at all stages of the FLBs’ development and usage.

Life Cycle Carbon Assesessment

A Whole Life Cycle Carbon Assessment found that HUSK reduces Global Warming Potential (GWP) by 62% compared to standard sustainable builds.

Key Findings of the assessment

-

62% GWP Reduction – Far exceeding typical sustainable construction.

-

Low-Carbon & Reused Materials – A deliberate focus on low-carbon and reused materials significantly minimises environmental impact.

-

Biogenic Carbon Storage & Reuse Benefits – Factoring these in would make HUSK carbon-negative.

-

90% Material re-use - Future HUSK deployments will have an even lower environmental impact.

“The 62% reduction represents an extremely significant improvement over conventional building practices—potentially twice what is expected from a typical sustainable new build. This is achieved through the selection of low-carbon materials at every stage and a conscious effort to incorporate reused materials wherever carbon-intensive materials would otherwise be required. Furthermore, if both biogenic carbon storage and Module D were factored in, the project would be carbon-negative several times over.”

JAW Sustainability

Download

HUSK Principles of Deployment August 2025